Presented by: Eng. Agr. Jorgelina Lezaun

Agribusiness & Marketing Consultant

jorgelina.lezaun@gmail.com

November 2024

Application of pesticides

The ground application of phytosanitary products can be done as:

|

To achieve effective treatments, the recommended doses and flow rates on the product manufacturer's label must be respected and the variables must be correctly combined: nozzle/nozzle flow rate, separation between nozzles and forward speed in order to place the appropriate dose on the target with an appropriate volume per hectare.

Correct application of phytosanitary products

The requirements considered in the design of a mounted, semi-mounted, free-wheeling and self-propelled agricultural sprayer, assisted or not by air curtain, are based on ISO, EN and IRAM standards.

There are procedures in place to ensure safety during the application. In addition, it is necessary to:

|

Regarding the spraying equipment, it must be verified that it is in optimal conditions to apply the recommended volume per hectare by checking that:

|

In addition, if you have tools and spare parts (filters, spray nozzles), verify that there are no liquid leaks and the controls and control instruments work properly.

Recomedations

Before spraying

Since people not directly involved with spraying may also be affected by the operation, it is advisable to warn neighbors, community groups, institutions, beekeepers etc. before the application.

If necessary - notify emergency services and local water and environmental authorities.

|

It should be noted:

|

Initial checks of the sprayer can be carried out without clean water, but with the operator wearing safety clothing.

- Check structures for operator safety such as steps, handrails or protective rails.

- Check the PTO (Power Take-Off) guards which must be in place, anchored and lubrication points examined. Rotate the pump by hand to ensure it is free.

- Check tire pressure and wear on towed machines.

- With clean water in the tank, operate sprayer above the working pressure to check for hose leaks, as cracks reduce hose performance and will increase foam in the tank.

- Check hose connections. Make sure the pressure gauge reads zero when the sprinkler is not working.

- Check the operation of the pressure control and release system, and ensure that the return to the spray tank agitation system is effective.

- Check boom height adjustments on tractor mounted sprayers and the spray controls, both while spraying and off, and the operation of the valves on each individual boom section.

- Flushing devices must also be in good condition and free of blockages and operators must understand the sequence of events when operating the valves to fill the tank.

- Selection of nozzles to be used can be made according to the label recommendation, which should suggest the nozzle type, spray angle, and liquid flow rate at a given pressure.

- Never mix nozzles on the boom (spray angle or flow rate) and ensure that spray patterns are free of lines and overlap properly off the boom and nozzles.

- The replacement period for spray nozzles will depend on their material, the agrochemicals applied and the working conditions. Regarding the material, nozzles with ceramic inserts have a longer life and those made of bronze or brass wear out more quickly. Polymer and stainless steel have an intermediate life.

Effects of nozzle wear on flow and distribution

Effects of nozzle wear on flow and distribution

During the application

The spray equipment should be calibrated:

|

What is “equipment calibration”?

Calibration (or fine-tuning) of spray equipment is the necessary procedure to achieve efficient application.

It includes the operation of the equipment and the result of its work in the real environment (crop situation, pest, product and climatic environment) for which it is necessary:

- Condition and adjust the correct operation of the spraying system (cleaning, decontamination, repair).

- Check spray uniformity.

- Check the quality of the spraying by the coverage achieved (drops/cm2).

Sprayers coupled to automatic monitoring systems (liquid flow rate, area covered) must be calibrated regularly and compared to the manufacturer's calibration figures.

Factors influencing calibration

There are three main factors that influence sprayer calibration:

- Speed rate

It can be calculated by timing the speed of the tractor/operator over a measured distance, over a surface similar to the one to be treated.

- Swath width

It is the effective swath covered by the nozzle or boom assembly. It may be calculated for one nozzle or the entire boom. Swath width for UBV drift spraying is usually determined by the row width and may be reduced as the row spacing is closed to allow for increased droplet deposition with each pass. Where a boom sprayer is to be used, the coverage width may be calculated by multiplying the number of nozzles by a distance between individual nozzles. For canopies of fruit trees or orchards, the swath width will be the distance between tree rows.

- Liquid flow rate

Nozzle flow rates at a given pressure can be obtained from the nozzle manufacturer's data sheets. The information is generated when applying clean water and is similar to applying conventional aqueous spray volumes at 150-300 L/ha. This is different when applying low volume treatments at higher concentrations. When measuring actual nozzle flow rates test at least one nozzle from each boom section and average the total.

Calibration steps

Calibration of an agricultural sprayer

You need to know:

- Volume of water (L/Ha) to be applied per hectare of the product, which will depend on the crop density, growth stage and location of the target to be controlled. The application instructions are written on the label of the phytosanitary product, and it is mandatory to read them before starting the calibration.

The application volume (L/Ha) is a decision that is made “a priori” to the application.

Speed (km/h) of the vehicle during application. The values of these parameters will be determined by the operator and will be appropriate for the treatment conditions.

As for speed, you usually have a speedometer that measures it. If not, it can be calculated by measuring the time it takes to travel a given distance. (You must travel a previously measured distance - not less than 100 m - and measure the time in seconds to travel that distance).

|

Once the volume of water (L/Ha) and the speed (Km/h) are known, the nozzle flow rate (L/min) is calculated. Normally the unknown is the nozzle or tip flow rate. |

- Nozzle flow rate (L/min)

-

To distribute a VOLUME OF WATER (liters), on a surface of one hectare (Ha), with a constant SPEED (km/hour), the nozzles will need to distribute a certain volume of water (liters) for a time (minute), which we will call the NOZZLE FLOW RATE (liters/minute).

The separation, space/distance between nozzles is a constant value for a sprayer, but given the working speed, it is a management decision.

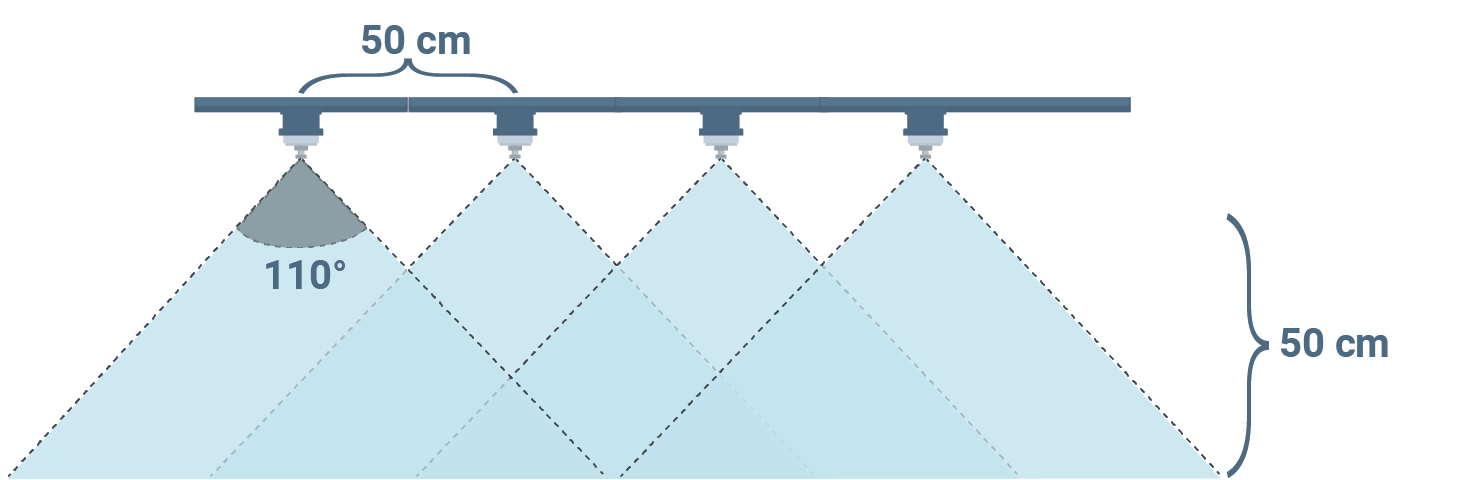

In Argentina, the most common distance for national sprayers is 0.35 m between tips and in cases where there are drops for fertilizers every 0.50 m or 0.52 m.

E.g. The separation of the nozzles/tips on the boom is 50 cm.

Once the flow rate has been defined (based on the type of application and assessment of atmospheric conditions), the type of nozzle/tip and the working pressure are selected to suit the desired droplet size. If necessary, a final adjustment of the flow rate is made based on a formula that relates pressure and flow rates.

Selecting the NOZZLE

The nozzles are manufactured according to international standards ISO/DIS 10625. The reference code and color indicate a certain nozzle orifice size and therefore the FLOW RATE (Liters/minute).

In the flow tables, you can look for the flow rate closest to the calculated NOZZLE FLOW RATE (Liters/minute), but taking into account that this flow rate will have to be produced with the pressure most appropriate to the treatment conditions.

Working pressure (bar)

Once the ISO nozzle has been selected, the new WORKING PRESSURE must be known. to be able to apply the calculated NOZZLE FLOW RATE which will be adjusted on the sprayer pressure gauge

For band applications: the criteria is similar, the basic formula is also used but the distance between nozzles will be replaced by a value that we will call “W”.

- When using only one nozzle per band: W = belt width (in meters).

- When more than one nozzle is used per band: W = distance between bands (meters) divided by the number of nozzles per band.

Calibration of the backpack sprayer

The backpack sprayer, as a portable device, also offers efficient performance if properly calibrated. It can be used interchangeably for spraying with insecticides, herbicides or fungicides with the support of the appropriate adjuvants.

Its calibration protocol must be followed to achieve efficiency and effectiveness.

Once the backpack sprayer is checked and in good condition, it is calibrated. First, the quantity of liters to be sprayed per hectare (L/Ha) and the required coverage per cm2 are calculated. Then, the width of application, the flow rate of the nozzle, the pressure and the working speed must be established.

- Check good conditions (both for a nozzle or with a boom with tips).

- Check that there are no drips on the boom, tips or nozzles -with the tank full of water- and that the nozzles are worn < 15%.

- Set the working width of the boom to 2 meters and then calculate the sprayed surface.

- Load the tank with a precise amount and spray that water in a straight line for a set distance at the same rate of speed along the path to achieve uniformity of application in the area.

- Pour the remaining liquid into a container to calculate the amount used in the application.

- These data are used to make estimates for spraying a given area.

- In the case of single-nozzle backpack sprayers, the application width is established and the same procedure is followed.

- Finally, a simple operation will determine, based on the capacity of the backpack, how many loads will be necessary to cover the total area.

- Once the spraying equipment has been calibrated, the tank is filled.

Recommendations for filling the tank

- Wear appropriate protective clothing when handling formulated pesticide and filling the spray tank. The spray operator is at greatest risk when handling concentrated pesticide. Where closed transfer systems are used to fill the tank, operator contamination is reduced.

- Liquid formulations are the most popular, easy to measure and empty. The spray tank is filled halfway with water and the pump is connected to give a gentle agitation. Products should be introduced into the tank according to the label recommendation, usually in the order of solids followed by liquids.

- Clean transfer systems after each use and valves - which must be designed - so that they do not leak when dry stop couplings are operated.

- Use secure containers and when there are appreciable distances for the sprayer and containers do not leave unattended, they must always be closed and secured against unauthorized interference.

- All operators must be fully trained in the procedures and any potential risks.

After spraying

- Do not spray against the wind, never apply when the wind is blowing towards a community or water source, or work with winds with speeds greater than 13 km/h.

- Respect the buffer distance.

- Do not spray with relative humidity < 50% and temperatures > 25 degrees Celsius because this promotes evaporation of the droplets.

- If necessary, use adjuvants, anti-drift, anti-evaporation products.

- Work with the boom as low as possible, as far as the stability system and uneven ground allow.

- It would be advisable to use two-meter-high anti-drift towers placed at 10, 20, 50 and 100 meters from the lot boundary and in the direction of the wind, where hydrosensitive cards will be placed to verify the existence or not of impacts caused by drift.

- During treatment, the product should not be applied in natural vegetation areas close to the plot. These sites are of great importance as habitats for beneficial insects and local fauna.

- Have new nozzles available for replacement if necessary.

- Do not eat or smoke during application.

- Finish the remaining spray solution on the same treated field.

How can application coverage be assessed?

- The analysis of the spray coverage can be verified on the target surface through the size of the drops produced as the number of drops applied per unit of surface (drops/cm²).

- For this analysis, hydrosensitive cards are used which are placed inside the crop in order to collect samples with the impacts of the spray drops in real working conditions.

- Hydrosensitive cards are a useful tool to evaluate the distribution pattern and droplet size and ensure application uniformity.

Good cleaning and storage practices

It is always recommended to follow the guidelines indicated by Good Agricultural Practices (GAP).

Inadequate management of agrochemical products, including their solid and liquid waste, can result in soil and water contamination, affecting the health of the population and the environment.

Remediating contaminated water and soil is difficult, expensive, slow, and in some cases irreversible. The best strategy is to promote the use of technologies that prevent contamination.

An alternative is the use of biological bedding or to define a delimited washing area, away from homes and water sources, for subsequent management and treatment in accordance with the requirements of environmental legislation.

|

Reference:

Triple wash video

Collection of containers (spanish version)

Poster Storage of containers

Biological beds Available course

Sources:

- Manual for agricultural applicators Responsible and efficient use of phytosanitary products Cid, Ramiro and Masiá, Gerardo Editorial Coordination: Bogliani, Mario 1st Edition National Institute of Agricultural Technology - Agroindustry Research Center

- Agricultural spray tablets, their correct selection and use for optimal application quality INTA Pedro Daniel Leiva

- Inta - Good Practices for the application of phytosanitary products / Brambilla V. Gómez Hermida M. Bogliani

- Sprayer Calibration How to perform a safe and efficient application, taking care of costs and the environment? Eng. Mag . Fernando R. López Rodríguez*

- Field Bugs INTA Drifts in Application of Pesticides in Critical Areas

- Argentina Gob.ar Application of pesticides in critical areas. Eng . Rubén A. Massaro. INTA EEA Oliveros.

- FAO Manual for the Preparation of Pesticides CASAFE Manual for the Responsible Use of Phytosanitary Products 2020

- Bulletin of Disclosure N°41 ISSN 0328-3380 Guide for the proper use of pesticides and the correct disposal of their containers Agr. Eng. Fanny Martens INTA - Rural Extension Agency Tandil May 31, 2018

- INTA EEA Oliveros. Popular Article Keys to minimize the drift Eng Agr. Ruben A. Massaro

- Evaluation of plant barriers to mitigate spray drift Lic. Copes Walter EEA Alto Valle. INTA National University of Comahue Faculty of Engineering Master's Degree in Environmental Intervention. Environmental Engineering Orientation

- CASAFE Preventing drifts in the application of phytosanitary products

- INTA Reports Precise Applications: How to Control Drift